Key Takeaways

- The Sikaflex 291 is a polyurethane adhesive with a fast-drying formula that is waterproof and permanent.

- The Sikaflex 292i is also similar but more upgraded than the 291, and it offers better bonding strength.

- The 3M 5200 suppresses both Sikaflex adhesives when it comes to bonding strength but has a lower temperature resistance compared to the Sikaflex 292i.

If you want to be more insightful about some of the best marine sealants, you will find today’s Sikaflex 291 vs. 3M 5200 vs. Sikaflex 292i comparison article helpful.

These sealants are versatile and can be suitable to use above and below waterline, and last a long time.

So read on to find out more!

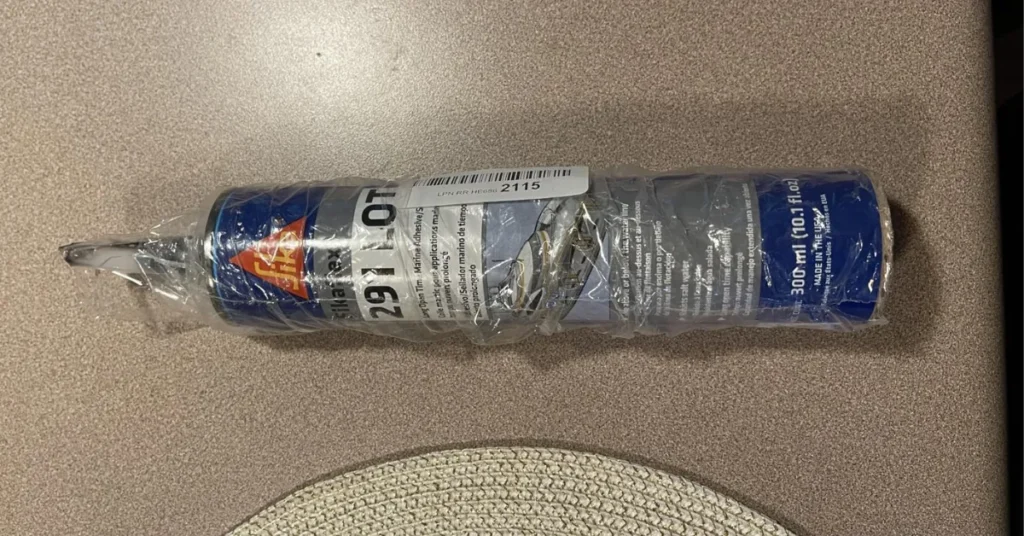

Overview of Sikaflex 291

The Sikaflex 291 is a 1-component polyurethane sealant mostly used as a marine adhesive.

It is reliable for strong bonding, can withstand exposure, and cures with the help of moisture.

On top of that, you can easily sand or paint over the adhesive once it’s fully cured.

Overview of Sikaflex 292i

Similar to the Sikaflex 291, the 292i is also a 1-component polyurethane marine adhesive.

This paste-like sealant does not sag and resists a higher temperature than most such sealants.

The Sikaflex 292i creates a stronger bond and has a fast drying and curing formula.

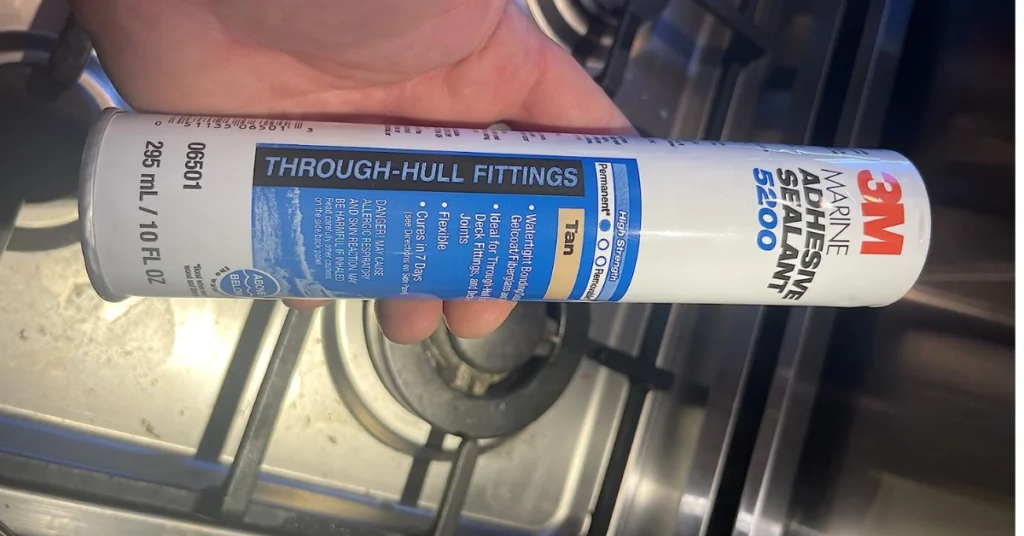

Overview of 3M 5200

The 3M 5200 is one of the most popular and powerful sealants out there, and it is made to last longer.

With its polyurethane base material and a higher tensile strength. On top of that, it allows you to

The drawback of this adhesive is that it is more expensive than the other two., but has a longer shelf-life.

Sikaflex 291 vs. 3M 5200 vs. Sikaflex 292i

Adhesive Base

The Sikaflex 291, 292i, and 3M 5200 are all polyurethane-based adhesives.

Such glues are more flexible, tough, and robust than regular adhesives.

That means you can use all 3 of them for multiple purposes and for a variety of projects.

Physical Form and Application

The Sikaflex 291 and 292i come in elastic form, meaning they appear more like gel.

That’s an advantage because such adhesive will not sag and create a mess during the application.

The 3M 5200 also comes in paste form, which is not saggy or messy, unlike liquid adhesives.

Compatible Materials

Talking about materials! You can use the Sikaflex 291 for bonding metal, gel coat, fiberglass, wood, etc.

The Sikaflex 292i is more versatile in this regard, as you can use it to fix metals, aluminum, wood, gel coats, fiberglass, floors, shower stalls, cabinets, and more.

In fact, this sealant creates a stronger bond in metal and aluminum materials than the 3M 5200.

If you are fixing a boat, the 292i will work better than the 291 if you are joining the hull to deck. Because it is more suitable for “no-movement” areas.

Similarly, the 3M 5200 is suitable for use on various materials, such as deck, hull, fiberglass, portholes, moldings, wood, etc.

But you must not use it on polycarbonate, glass, or acrylic windows.

Water and Temperature Resistance

The Sikaflex 291 works in temperatures between -58°F and 194°F, which is the same for the 292i.

As for the 3M 5200, it works best at -40°F to -190°F temperature, meaning its temperature resistance is slightly lower than the Sikaflex adhesives.

Nevertheless, these sealants offer a better and durable resistance to water and you can use them below and above the water lines. They even resist saltwater.

Other Resistance

Other than water, both Sikaflex 291 and 292i resist diluted acids and caustic solutions.

They also offer temporary resistance to mineral oils, vegetable, and animal fats, fuels, etc.

The 3M 5200 has a weather-resistance formula, which allows the adhesive to stay firm throughout shocks and vibrations.

But you mustn’t use it as a teak deck seam sealer or expose it to gasoline or any other strong solvents.

Drying and Cure Time

All 3 of these adhesives require moisture to dry and cure. So, the drying and curing time mostly depend on the temperature they are in.

Nevertheless, with their fast-drying formula, both Sikaflex 291 and 292i begin to dry and skin in 60 and 40 minutes, respectively.

On the other hand, the 3M 5200 takes much longer. Though it starts creating the bond 15 minutes after application, the adhesives will start to skin after 48 hours and take 5-7 days to cure completely.

Bonding Strength

The Sikaflex 291 has a tensile strength of 260 psi, whereas the 292i has that of 550 psi.

But the 3M 5200 beat them both with a higher tensile strength of 700 psi.

Convenience

These one-part adhesives are no hassle when it comes to straightforward use.

Besides, they are flexible and offer adjustability, thanks to their lengthy open time.

Moreover, once the adhesives harden and cure, you can easily sand and paint over them.

Shelf Life

The 3M 5200 has a longer shelf life than the Sikaflex ones.

While both adhesives from Sikaflex can be stored for 12 months, the 3M 5200 has a shelf life of up to 24 months.

Cost

When comparing all three adhesives, the Sikaflex 291 turned out to be the most affordable one.

On the other hand, the Sikaflex 292i is more expensive than the 291 sealant.

As for the 3M 5200, it is even more expensive compared to the other two.

However, the price of the Sikaflex 292i and 3M 5200 can be a little competitive based on the cartridge size, retailer, available offer, etc.

Editor’s Opinion

Comparing the Sikaflex 291 vs. 3M 5200 vs. Sikaflex 292i has been fun for me as they are similar yet different in their own ways.

While the Sikaflex adhesives dry and cure faster, the 3M 5200 takes its time and yet offers a more durable bond.

Nevertheless, these sealants are excellent for a variety of projects. So you can pick the one that fits your purpose best.